With magnetic resonance bulk ore sorting for maximum resource conservation in mining

Even less water requirement with pre-sorting

A central point for the mine of the future is economically feasible answers to the increasing pressure to become more sustainable and drastically reduce water consumption. One of the most efficient methods for saving water is the combination of pre-sorting with MR technology and subsequent dry grinding in an MVR mill. Both processes almost completely eliminate the use of water in the early process stages, providing you with significantly more economical and environmentally friendly raw material extraction. We have compiled the first aspects for you here. For all further details, our experts at the Pfeiffer Technikum are available to you.

NextOre magnetic resonance: A breakthrough in ore analysis

Magnetic resonance technology - MR for short - developed by the CSIRO, Australia’s science agency and exclusively manufactured and distributed by our partner NextOre revolutionises the detection and grading of ores by enabling precise and volumetric measurements of specific mineral content. Similar to magnetic resonance imaging (MRI) in medicine, this process uses specifically tuned radio frequency pulses that are targeted at the characteristic resonance frequency of certain minerals. The strength of the measured signal is highly penetrative directly related to the mineral content, allowing for an exact, quantitative, and in-depth analysis.

Your benefits with MR bulk ore sorting

High-performance sorting without pre-treatment

The advanced MR technology analyses thousands of tons of crushed ore per hour - completely without screening or washing and thus completely without the use of water. It performs large-volume content measurements within seconds, enabling the immediate grading of specific ore.

Real-time monitoring for optimized processes

By providing immediate ore grade measurement in real-time, you can autonomously control and optimise your downstream processes. This results in even more efficient resource utilisation, further reducing energy and water consumption, and increasing your metal yield.

How You benefit from the combination of dry sorting and dry grinding

Secure a unique process chain with unbeatable advantages with the highly efficient combination of powerful MVR dry grinding and pre-sorting with MR technology. Save even more water, energy, infrastructure, and disposal costs. And easily meet even the strictest environmental regulations.

- precise material grading through safe radio frequency technology

- no water consumption for precise and fast sorting

- less use of chemicals through early separation of unusable material

- higher efficiency and increased metal production through targeted processing of only usable material

- flexible adjustment of grinding parameters to the pre-sorted material

- maximum water savings through dry pre- and post-processing

- easier dewatering of tailings due to lower fine content

- lower energy consumption and reduced operating costs

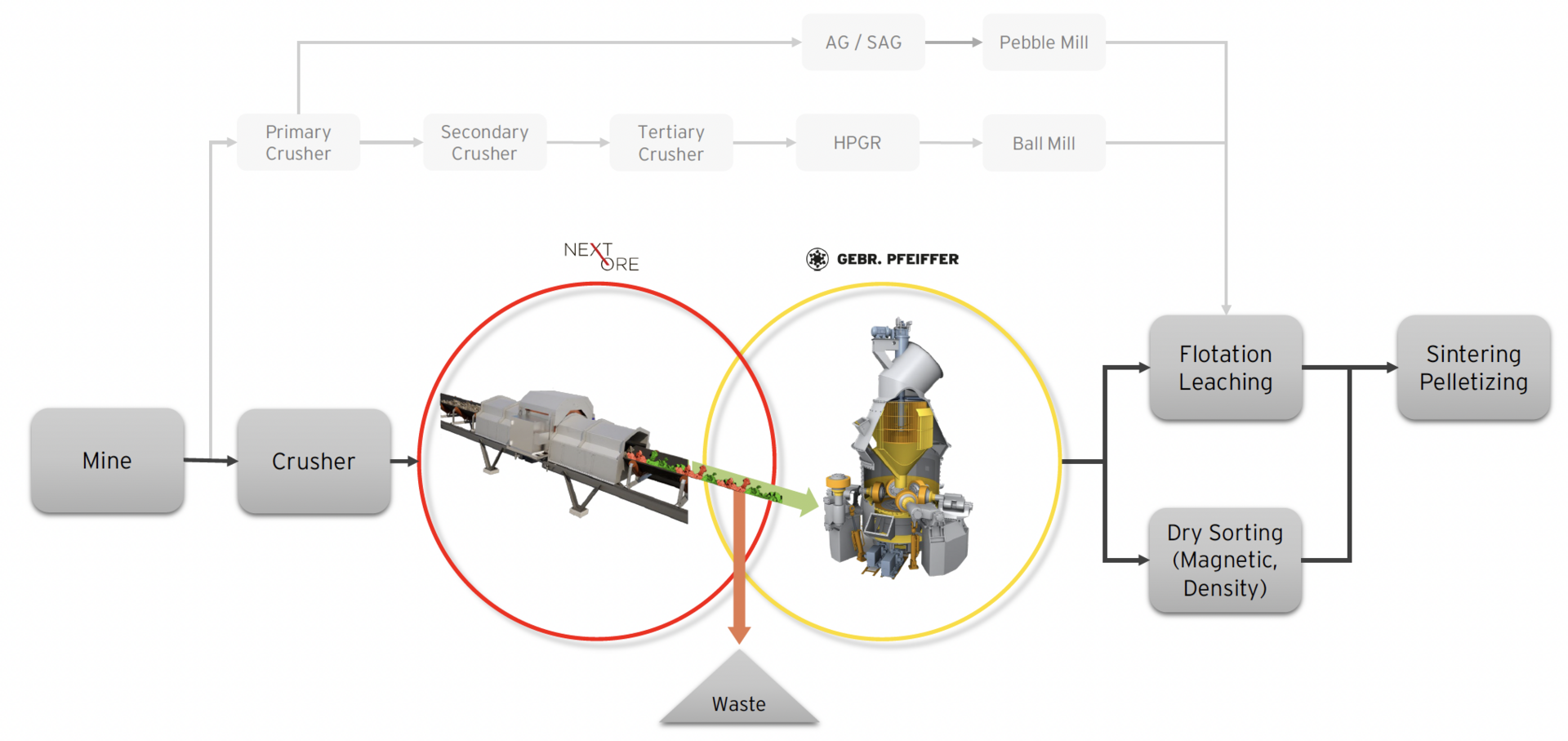

This is what your efficiency and sustainability optimized process could look like

AG / SAG Ł Pebble Mill Primary Ł Secondary Tertiary Ł Crusher Crusher Crusher HPGR Ł Ball Mill Sintering Pelletizing Mine -Crusher Dry mass sorting in advance plus dry grinding in an MVR vertical mill. All in a lean, adaptive process that requires little infrastructure and allows you to respond flexibly to changing conditions.

Start now into the future of resource-conserving ore processing!

Rely on the ideal combination of MR bulk ore sorting and MVR dry grinding, reduce the water consumption of your ore processing to a minimum, and benefit from many other efficiency advantages. Contact us now for a customized, sustainable solution! Gebr. Pfeiffer SE